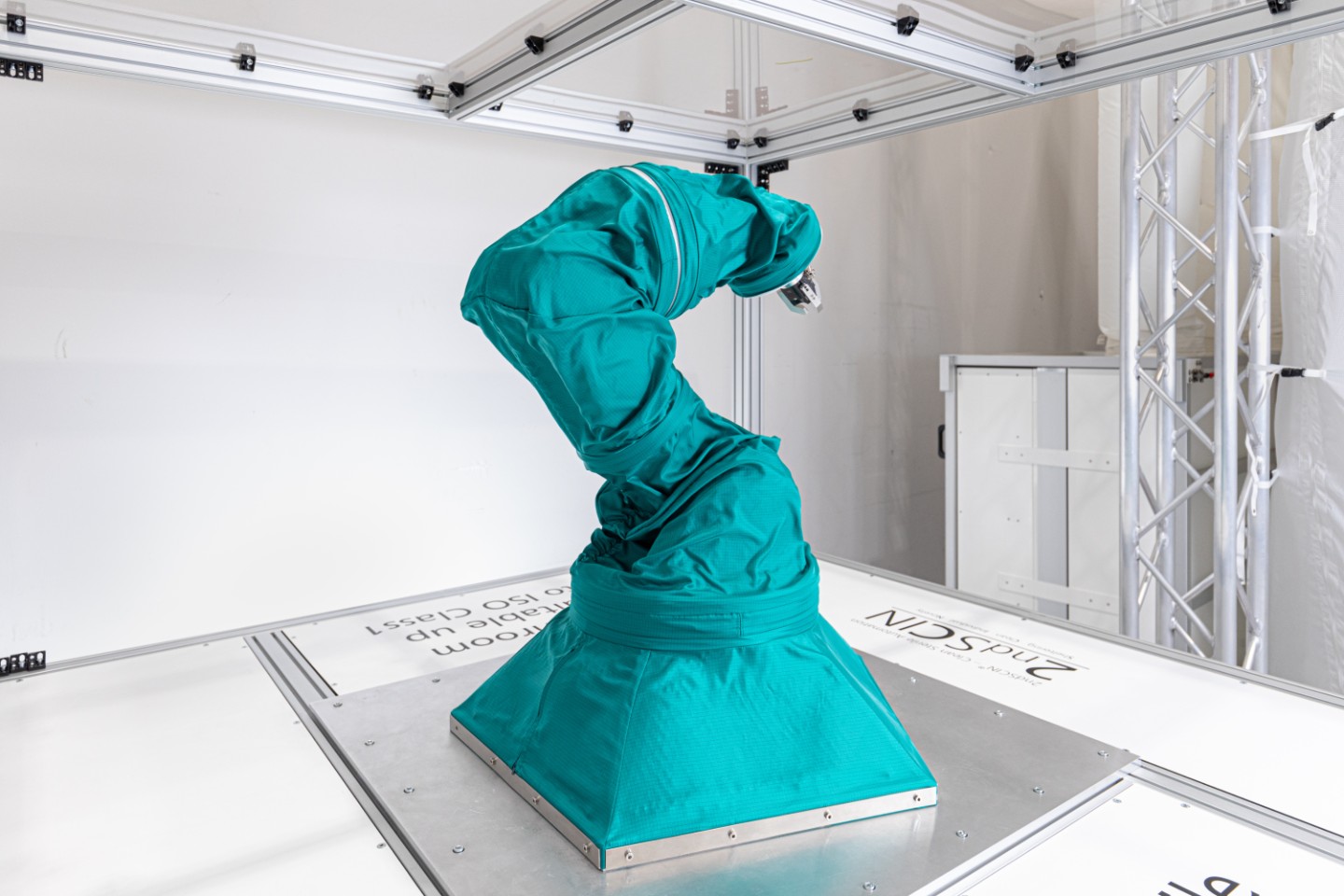

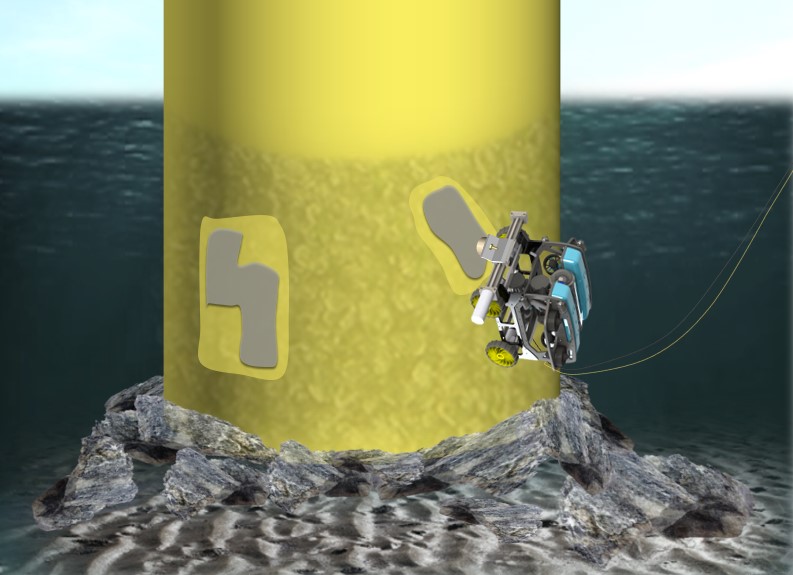

Additive technologies offer a number of advantages over traditional, subtractive machining processes, but generally only deliver semi-finished products, as the surface quality of additively manufactured components is often inadequate or support structures have to be removed. The final added value is therefore created through post-processing. Depending on the material and the functional and quality requirements, various technologies are available for post-processing the component surface.

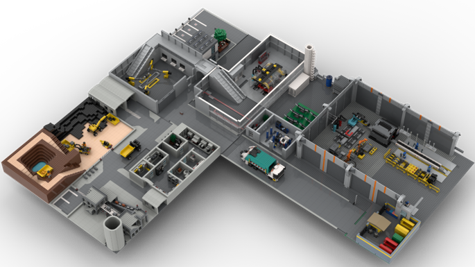

To this end, the Fraunhofer Group for Production is presenting a joint exhibit in the form of a turtle in the »Production Technologies« area. The turtle presents haptically innovative post-processing technologies for additively manufactured components.

Fraunhofer Group for Production

Fraunhofer Group for Production