Description Language »PFDL«

A key feature of SWAP-IT is the "PFDL" (Production Flow Description Language), an in-house development by Fraunhofer researchers.

The decisive advantage: Since the PFDL specifies the basic sequence of workflow steps, but not which machine takes over which task, the SWAP-IT software decides how exactly the job is to be executed and assigns individual tasks to machines that are currently available or conveniently located. The production system considers a variety of factors.

Each task is executed individually and efficiently according to the specifications. In classic manufacturing with its standardized workstations, this case-by-case flexibility is not achievable.

Individual Objectives

The responsible workers can also specify that the production process should be particularly energy-efficient or fast, or that it should be carried out with maximum utilization of the plants and machines.

If a spontaneous order peak occurs, employees can set fast production as a target for the system, even if this results in higher energy costs in individual cases. The production can thus easily react to repeat orders or to the modification of product features in the case of a new product version.

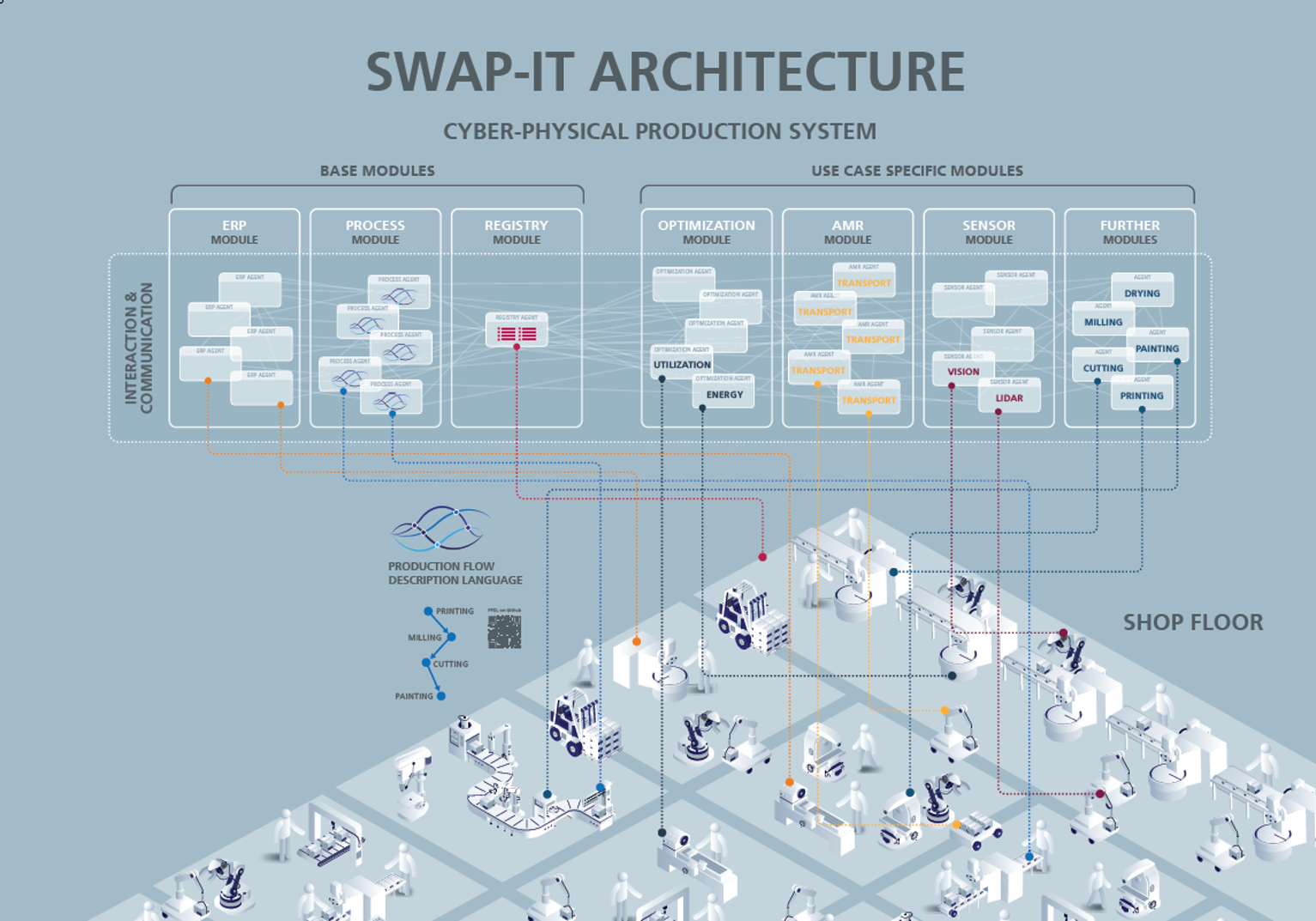

A logical complement to Industry 4.0

As part of the Industry 4.0 megatrend, technologies such as sensors, networking and digital twins have found their way onto factory floors. The lighthouse project SWAP aims to be a continuation of this trend. SWAP-IT uses data to liberate production from stiff processes.

Fraunhofer Group for Production

Fraunhofer Group for Production