Modern industrial production is precision work in more than one respect. Products are manufactured to exacting standards, requiring machine tools’ mechanics to operate reliably and with uncompromising accuracy – unwanted vibrations for example can cause flaws in the required product geometry and lead to expensive waste. Similarly, manufacturing processes usually follow a tight schedule. disruptions or machine breakdowns mean lost time and, potentially, incur contractual penalties when delivery deadlines are missed.

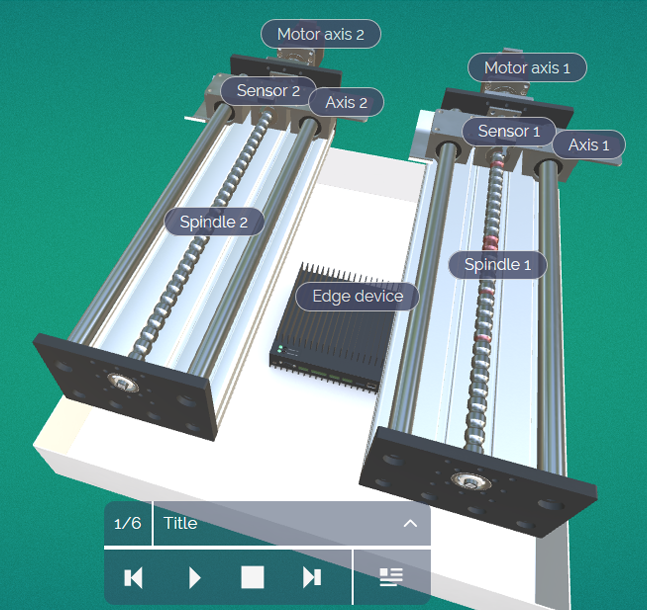

Smart and predictive maintenance is meant to recognize any signs of damage or wear and tear in machine components at the earliest possible time in order to avoid unplanned and unexpected failures. Sensors fitted to machines keep track of active operations and measure temperature, vibration, energy consumption, and many other parameters. Whenever there are deviations from the norm or signs of potentially problematic trends, the system triggers an alarm so that operators can start countermeasures. However, most commercially available monitoring systems remain isolated proprietary solutions that only track the condition of individual components.

Fraunhofer-Verbund Produktion

Fraunhofer-Verbund Produktion